One Hour One Life Forums

a multiplayer game of parenting and civilization building

You are not logged in.

- Topics: Active | Unanswered

Pages: 1

#1 2019-05-24 18:55:58

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Recipe Suggestions Mega-Thread

INTRODUCTION

Starting this mega-thread to keep track of recipe suggestions.

My other mega-suggestion thread kind of derailed into radical/unfeasible ideas, so the goal is to keep this one simple and manageable to implement. Feel free to add your own suggestions, but tree to keep them in A + B = C + D format.

RECIPE 1: PINE RESIN

Pine resin is a popular material used in bushcraft, and was extensively used by many primitive societies. Notably, pine resin was the easiest source of adhesive (glue!!) and waterproofing material. Pine resin is also naturally antiseptic (can be used to stop wounds) and flammable (used in torches/lamps).

Formula:

1. White Pine Tree + Knife = Slashed White Pine Tree

2. Slashed White Pine Tree + (Time) = White Pine Tree with Resin

3. White Pine Tree with Resin + (Action) = Pine Resin + White Pine Tree

RECIPE 2: PINE PITCH

Pine pitch is one of the earliest forms of natural glue. Pine pitch was used to haft arrowheads to arrows, celtic stone axe heads to axe shafts, etc. Additionally, pine pitch will waterproof and seal containers. Pine pitch was used to seal boats, barrels, and buckets. Tanned animal skins will not hold water, and the insides must be sealed with pitch in order to use them as water skins. Applying pine pitch to a basket could make it waterproof, and consequently water could be carried with something like a reed basket.

Pine pitch is liquid when hot, but will solidify once it cools down. Apply when hot.

Formula:

1. Pine Resin + Clay Bowl = Bowl with Pine Resin

2. Bowl with Pine Resin + Charcoal = Bowl with Pine Resin and Charcoal

3. Bowl with Pine Resin and Charcoal + Hot Coals = Bowl of Molten Pine Pitch + Hot Coals

4. Bowl of Molten Pine Pitch + (Time) = Bowl of Hardened Pine Pitch

5. Bowl of Hardened Pine Pitch + Hot Coals = Bowl of Molten Pine Pitch + Hot Coals

RECIPE 3: WATERPROOF BASKET

Many North American native cultures used baskets sealed with pine pitch to transport water. The most notable examples were made by Southwest Navajo Native Americans, who made very elaborate and decorative pine pitch baskets and pottery -- since water is one of the most precious commodities in the Southwest United States. Pine pitch baskets could be made larger and lighter than clay pottery, meaning it was more practical for transporting more water over long distances.

Formula:

1. Bowl of Molten Pine Pitch + Basket = Waterproof Basket + Skewer

Use (examples):

1. Waterproof Basket (0/3) + Pond/ShallowWell = Waterproof Basket (1/3) + Pond/ShallowWell (-1 use)

2. Waterproof Basket (1/3) + Pond/ShallowWell = Waterproof Basket (2/3) + Pond/ShallowWell (-1 use)

3. Waterproof Basket (2/3) + Pond/ShallowWell = Waterproof Basket (3/3) + Pond/ShallowWell (-1 use)

4. Waterproof Basket (3/3) + Clay Bowl = Waterproof Basket (2/3) + Bowl of Water

5. Waterproof Basket (0/3) + Bowl of Water = Waterproof Basket (1/3) + Clay Bowl

6. ...etc...

RECIPE 4: PINE RESIN TORCH

A really simple torch that burns for longer than a firebrand. Useful for carrying longer distances.

Formula:

1. Pine Resin + Long Straight Shaft = Pine Resin Torch

2. Pine Resin Torch + Fire = Lit Pine Resin Torch

3. Lit Pine Resin Torch + (Time) = Long Straight Shaft

Last edited by lychee (2019-05-24 20:04:05)

Offline

#2 2019-05-24 20:26:55

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

Recipe 5: Red Ochre

Red ochre was probably the first pigment extensively used by humans. Cave paintings are done with red ochre - it’s very abundant - and anthropologists believe that it is likely that early humans painted abundantly with various ochres. Body paint! Also burial sites of ancient humans are full of ochre (as a mineral, it never fades color).

Red ochre is derived from any iron-containing mineral. The pigment can be rubbed over the body in the absence of any binder, and it will stick (like a crayon). Alternatively, mix with a liquid like water, egg whites, or oil to get a liquid paint.

Formula:

1. (98%) Iron Ore + Round Stone = Red Ochre Pigment + Iron Ore + Round Stone

2. (2%) Iron Ore + Round Stone = Red Ochre Pigment + Round Stone

Last edited by lychee (2019-05-24 20:29:07)

Offline

#3 2019-05-25 14:19:00

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

RECIPE 6: FLAX

Flax is one the most famous ancient fiber plants, used to make rope, linen, and linseed oil. It was used by Ancient Egyptians, Sumerians, and was the most common textile in Europe for thousands of years (Linen!). It makes sense to have it, if you want anything linen (clothes, canvas, sails)!

Flax grows, flowers, seeds, should be harvested when it starts to turn yellow.

The procedure for harvesting flax has multiple steps (similar to wheat), but given the simplifications in OHOL, it seems that many steps could be skipped or switched to stay consistent with other plant products in OHOL.

I'll start with the realistic description: First, flax is pulled by hand to harvest (no need for sickle). It is laid out to dry (2-3 days), and then threshed to remove the seeds (similar to wheat). Next the straw is retted by soaking it in water (e.g. pond/river -- in theory you have to do this with milkweed too). After retting, the flax fibers are separated from the stalks by beating it and combing away the straw debris. This flax fiber can then be spun (on drop spindle or spinning wheel) into thread (also potentially into rope). Note that flax is 2-3x stronger than cotton and European did use flax as their bowstrings.

Formula (adjusted):

1. Flax Plant (fully grown) + (action) = Flax Sheaf + Hardened Row

2. Flax Sheaf + Curved Branch = Flax Straw + Flax Seeds + Curved Branch

3. Flax Straw + Pond + (time) = Retted Flax Straw + Pond

4. Retted Flax Straw + Round Stone = Flax Fibers + Round Stone

RECIPE 7: FLAX THREAD AND ROPE

1. Flax Fibers + Drop Spindle = Flax Thread

2. Flax Thread + Flax Thread = Rope

3. (Linen making process)

RECIPE 8: LINSEED OIL

Linseed oil is most famous for its use as a paint binder (make oil paint using pigments). It is also used to varnish wood, preserving it and extending its shelf life. It is also edible. Traditionally, linseed oil is cold-pressed.

In OHOL, we lack a seed/oil press device (traditional ones use very large stones driven by animals -- not very feasible to do this by hand) (renaissance/pre-modern ones used a screw press). I'll leave out the design for an oil press for now, but it would be worthwhile to consider it at some point.

Offline

#4 2019-05-26 03:20:22

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

RECIPE 9: OXEN

Oxen are some of the earliest animals domesticated by human beings -- and they were especially critical in agriculture for ploughing fields. In this recipe series, I propose a system for implementing oxen and animal ploughing.

For simplicity, let's say a fed Domestic Bison has a 50% chance of producing an ox (male) and 50% chance of producing a cow (female).

RECIPE 10: YOKE

A yoke is a generic attachment used to attach a pair of oxen to some tool extension. The tool extension can be variable, but is classically exemplified by something like a plough or cart.

Formula:

1. Long Straight Shaft + Flint-tipped Bow Drill = Long Straight Shaft with Single Bore + Flint-tipped Bow Drill

2. Long Straight Shaft with Single Bore + Flint-tipped Bow Drill = Long Straight Shaft with Double Bore + Flint-tipped Bow Drill

3. Long Straight Shaft with Double Bore + Rope = Long Straight Shaft with Double Bore and Rope

4. Long Straight Shaft with Double Bore and Rope + Rope = Yoke

RECIPE 11: Yoked Pair of Oxen

1. Yoke + Domestic Ox = Yoke with Single Ox

2. Yoke with Single Ox + Domestic Ox = Yoked Pair of Oxen

RECIPE 12: Wooden Ard

The wooden ard was the earliest form of plough, employed extensively by the Egyptians and Vikings. The ard can also be witnessed in many modern primitive/poor cultures -- for instance, in Ethiopia. Ploughs were critical for human agricultural revolution, and most major ancient civilizations/cultures/farmers employed them. Large-scale farming with digging sticks or hoes was not practical or economical in most circumstances.

Ploughs provided two benefits to human civilization. (A) Faster, easier ploughing. The original definition of an "acre" was the amount of land that a single man could plough in a day with an ox/horse. Compare this with the amount of land that could be ploughed using a stick or hoe -- there's no contest -- ploughing with animals was superior in every way. Consequently, even the poorest peasants in Europe ploughed with livestock rather than by hand. (B) Ability to cultivate tougher soil. Ploughs are able to penetrate harder soils than hoes/sticks. In Ancient Egypt, hoeing the ground was only viable in the softest loams/soils. The advent of the wooden ard allowed the ploughing of thicker soils. The later development of heavy plows (iron/steel) enabled the farming of tough soil like those in Northern Europe. In summary, ploughs allowed humans to extend their agricultural range beyond the softest soils.

Implementing these benefits are rather difficult in OHOL, especially since hoe-tilling is instantaneous and has no time cost. Rather, the main cost of farming is iron (when a hoe breaks) or rope (when a stone hoe breaks). If the goal is to make plough-farming superior than hoe-tilling, some artificial benefit most be created for ploughs.

Proposed benefits of ploughs:

1. Using an oxen-driven plough would be like riding a horse-drawn cart.

2. Everywhere the ox-team is driven, it ploughs the ground (provided soil is laid out already).

3. A wooden plough should cost less rope (or last longer) than a stone hoe, and an iron/steel plough should cost less (or last longer) than a steel hoe.

4. A plough "use" is only calculated when a player mounts/rides the ox team. Consequently, ploughing 10 adjacent tiles with an ox team without dismounting is equivalent to 1 use with a steel hoe.

5. When a plough breaks, only the attachment breaks (not the yoke).

Formula:

1. Long Straight Shaft + Flint-tipped Bow Drill = Long Straight Shaft with Single Bore + Flint-tipped Bow Drill

2. Small Curved Shaft + Fire = Hardened Small Curve Shaft

3. Long Straight Shaft with Single Bore + Hardened Small Curve Shaft = Wooden Ard

4. Wooden Ard + Yoked Pair of Oxen = Yoked Pair of Oxen with Ard

5. Yoked Pair of Oxen with Ard + (Action) = (Ride/Plough/Drive)

Last edited by lychee (2019-05-26 03:20:53)

Offline

#5 2019-05-26 04:57:15

- wio

- Member

- Registered: 2018-11-30

- Posts: 51

Re: Recipe Suggestions Mega-Thread

Wow lychee. You've put a lot of effort into this thread. How do you think these suggestions would affect the difficulty of the game?

Offline

#6 2019-05-26 05:41:12

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

Wow lychee. You've put a lot of effort into this thread. How do you think these suggestions would affect the difficulty of the game?

Hmm, assessing difficulty is hard without seeing the full tech tree in front of you.

For me personally, I think the game is more interesting with multiple parallel paths up the tech tree (e.g. more than one way to make a basket -- e.g. straw or reeds) and more depth added to flesh out the tech tree, particularly in the mid game before diesel tech. Also, there are major historical Earth industries (e.g. cotton, coal, bronze, nautical) that are glaringly missing from OHOL, and I think anyone is bound to wonder why they aren't in the game.

From a game design perspective, it is important for each tier of technology (e.g. skewer, stone hoe, plough, steel plow, tractor) to have noticeable improvements over the previous tier. However, the deeper I flesh out the tree -- the more I am starting to realize that there aren't very strong reasons to improve on older tech in the current game design. For instance, a steel hoe is already a great tool in OHOL, since all farming tools work instantaneously. Why would someone bother making a tractor for farming? Why should someone make nylon rope if they already have milkweed rope?

I think Jason discovered this problem with water -- a few months ago, nobody was teching to diesel wells because the mid-level water tech was already great (and gave infinite water). Consequently, in some circumstances, it may be appropriate to nerf current technology to make room for the relative tech advancement (making the game harder).

In the mean time, I do hope that adding multiple parallel paths would make the game easier too. At the very least, I hope there can at least be some ambiguity with regards to "only one way to play the game" monotonous meta gameplay (e.g. find green biome, swamps, rush sheep, compost, and diesel).

It is really a delicate balance in the end, and it is worthwhile for people to discuss whether certain additions are balanced in terms of gameplay or not. For me personally, it is a pipe dream that one day every major technology in the history of Earth will be represented in some way in OHOL. My personal gut instinct would be to balance the game according to how it is on Earth (e.g. mass berry farm to sustain a nuclear-powered civilization doesn't make any sense on Earth, so maybe OHOL shouldn't be that way either) -- however, it's really up to Jason to decide how he wants the game to be and shape the game in the way he thinks is best.

Offline

#7 2019-05-26 15:43:43

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

RECIPE 13: WILD YAM

Tubers and yams were a major part of the human paleolithic/hunter-gatherer diet. Yams are vine plants and they can also get enormous. Very starchy and nutritious. Traditionally they were dug up with digging sticks, but shovels will work. As a side note, it should be possible to dig up potatoes with a digging stick too (they are part of the tuber family).

Yam tubers vary in size from that of a small potato to over 60 g (2.1 oz). Some 870 species of yams are known,[1] and 95% of these crops are grown in Africa.[9]

Yam tubers can grow up to 15 m (49 ft) in length and 7.6 to 15.2 cm (3.0 to 6.0 in) high.[1] The tuber may grow into the soil up to 1.5 metres (4.9 ft) deep.[1] The plant disperses by seed.[1]

Formula:

1. Wild Yam + Skewer = Wild Yam (dug out) + Skewer

2. Wild Yam + Shovel = Wild Yam (dug out) + Shovel

3. Wild Yam + Coals = Cooked Wild Yam (3/3 uses)

4. Wild Yam + Hot Adobe Oven = Baked Wild Yam (3/3 uses)

Last edited by lychee (2019-05-26 15:46:55)

Offline

#8 2019-05-26 21:34:45

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

RECIPE 14: SPEAR

Implementation of a spear could be such that stabbing a bear has greater risks (could still be mauled), and there is a slowdown/cooldown between stabs. Aside from this, spears were the classic implement for hunting boars in the medieval era (although it was risky).

Formula:

1. Long Straight Shaft + Rope = Tied Long Shaft

2. Tied Long Shaft + Flint Arrowhead = Stone Spear

Offline

#9 2019-05-27 15:42:24

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

RECIPE 15: SINEW

Animal sinew is one of the oldest forms of cordage used by primitive humans. It is also one of the strongest natural fibers in the world (stronger than most plant fibers -- limited only by the quantity that is reasonable to produce IRL). Sinew stretches when wet and contracts when dry. Sinew should be worked with when wet.

Recipe has been balanced relative to milkweed. Ideally, multiple forms of skinned large animals (sheep, wolf, bear, boar, mouflon) should feed into this recipe.

Formula -

1. Skinned Large Animal + Flint Chip = Fresh Sinew + Skinned Large Animal without Sinew

2. Fresh Sinew + (Time) = Dried Sinew

3. Dried Sinew + Round Stone = Processed Sinew + Round stone

4. Processed Sinew + Bowl of Water = Wet Sinew + Clay Bowl

5. Wet Sinew + Wet Sinew = Thread

Last edited by lychee (2019-05-27 15:44:18)

Offline

#10 2019-05-27 16:36:59

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

In theory, technically all forms of animal skins needed to be "tanned" before they are made into clothes. Without a tanning treatment, animal hides literally rot, which means they decompose very quickly. Paleolithic humans discovered tanning very early -- and there are many methods to tan animal skins. Even if you see nice luxurious rabbit furs/pelts, etc, they have been tanned (although only on one side).

For the purposes of OHOL, tanning extends the shelf life of animal skins before they decay. Conversely, for balance, the shelf life of untreated animal skins should be nerfed.

RECIPE 16: RAWHIDE (SMALL/LARGE)

Rawhide is the term for animal skins that have not received tanning treatment, but has been preprocessed with scraping. When rawhide dries, it is actually very stiff and hard (used in things like drums) -- tanning is necessary to soften the hide.

In OHOL, I think it's reasonable to classify animal skins/pelts as either small (rabbit skin) or large (wolf skin, bear skin).

Formula:

1. Animal Skin + Pond = Soaking Animal Skin in Pond

2. Soaking Animal Skin in Pond + (Action) = Soaked Animal Skin + Pond

2. Soaked Animal Skin + Bowl of Slaked Lime = Limed Animal Skin + Clay Bowl

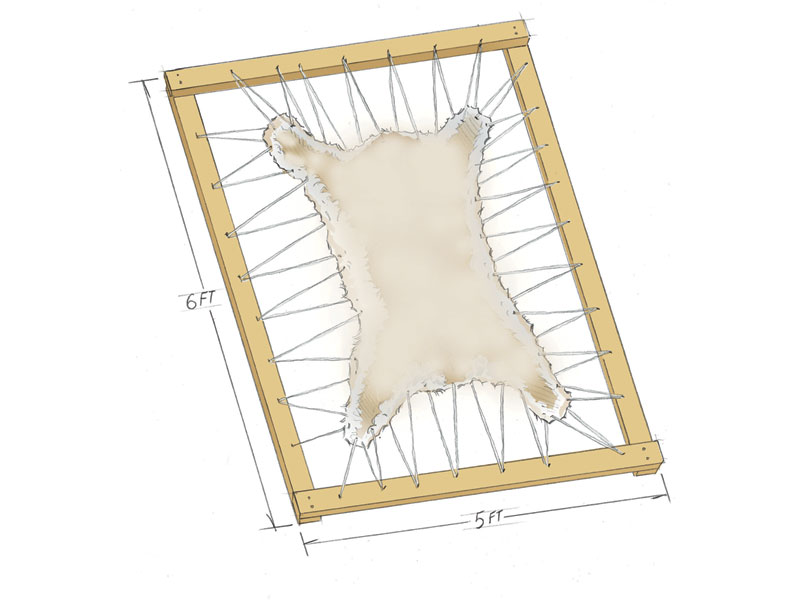

3. Limed Animal Skin + Wooden Frame = Stretched Animal Skin

4. Stretched Animal Skin + Flint Chip = Stretched Rawhide

RECIPE 17: FAT SOLUTION

One of the oldest methods to tan a hide was to use brains. Brains contain an oil that is very good for tanning. Various Native American cultures used this method. For OHOL's purposes, I think it's reasonable to approximate this as "Fat Tanning Solution".

Formula:

1. Raw Meat (e.g. mutton, rabbit) + Bowl of Water = Bowl with Raw Meat and Water

2. Bowl with Raw Meat and Water + Sharp Stone = Bowl with Mashed Raw Meat and Water + Sharp Stone

3. Bowl with Mashed Raw Meat and Water + Hot Coals = Simmering Bowl of Fat Solution

4. Simmering Bowl of Fat Solution + (time) = Bowl of Fat Solution

RECIPE 18: TANNIN

Tannin is a vegetable-based tanning agent. It was used predominantly in the 1700s/1800s Europe (and is incidentally where the term "tanning") comes from. Tannin is make from the bark of the oak tree (among other trees). OHOL lacks an oak tree (but tbh I'm going to assume that an oak tree is added -- oak is useful for lots of things! Why don't we have cedar trees?).

Hides tanned with tannin are stiffer and harder than other tanning methods.

Formula:

1. Oak Tree + Sharp Stone = Oak Tree + Oak Tree Bark + Sharp Stone

2. Oak Tree Bark + Clay Bowl = Bowl of Oak Tree Bark

2. Bowl of Water + Bowl of Oak Tree Bark = Bowl of Soaking Oak Tree Bark + Clay Bowl

3. Bowl of Soaking Oak Tree Bark + Hot Coals = Bowl of Simmering Oak Tree Bark

4. Bowl of Simmering Oak Tree Bark + (Time) = Bowl of Tannin

RECIPE 19: LEATHER (SMALL/LARGE)

Seems reasonable to divide leather up into small/large based on the starting material. Rabbits make small leather and large animals make large leather.

Formula:

1. Stretched Rawhide (still on frame) + Bowl of Tannin = Tanning Rawhide + Clay Bowl

2. Stretched Rawhide (still on frame) + Bowl of Fat Solution = Tanning Rawhide + Clay Bowl

3. Tanning Rawhide + (time) = Stretched Leather

4. Stretch Leather + (action) = Leather + Wooden Frame

Last edited by lychee (2019-05-27 16:43:00)

Offline

#11 2019-05-27 17:02:40

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

Note: Limestone should be fired in a regular kiln, not a forge.

The temperature required to fire lime (900C) is lower than that required to fire pottery. There’s absolutely no reason to require a forge with bellows.

Offline

#12 2019-05-27 23:42:12

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

RECIPE 20: Copper Ore (Malachite) Mine

Copper was one of first ores that humans learned to smelt. A number of copper ores are prevalent, but malachite (already in the game) was most famous -- in part because it could be found in limestone deposits (softer stone) that could be mined easily with primitive technology.

In this series, I push for bronze tech as a step before iron/steel, lengthening the tech tree overall. Consequently, a copper mine is necessary to fulfill the role of an iron mine in the copper age.

Formula -

1. Malachite Vein + Bronze Pick (or any tech pick) = Malachite + Bronze Pick (-1) + Malachite Vein (-1)

2. Malachite Vein (last use) + Bronze Pick = Malachite Pit + Bronze Pick (-1)

3. Malachite Pit + Stanchion Kit = Malachite Mine

4. Malachite Mine + (Action) = Malachite + Malachite Mine (-1)

Offline

#13 2019-05-27 23:57:35

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

RECIPE 21: Stone Axe (Celt)

The Celt is a primitive stone axe.

I wavered a little on whether to include it, but decided that having an axe in the stone age is an important quality-of-life feature. We already have a stone hoe, and there is evidence of stone-age axes. The difference between a stone axe and an iron one is durability -- stone ones break more easily.

The procedure for making a Stone Axe (Celt) actually involves using hard groundstone. These rocks are not made with flintknapping as other stone age tools (a concussion implement like an axe would break too easily), so the sharpening of these tools is feasible only by grinding. Consequently, a celt is far more durable than a typical stone age handaxe or other implement.

Formula:

1. Flat Rock + Bowl of Water = Wet Flat Rock + Clay Bowl

2. Wet Flat Rock + Sharp Stone = Stone Axe Head + Flat Rock

3. Long Straight Shaft + Flint-Tipped Bow Drill = Long Straight Shaft with Single Bore

4. Long Straight Shaft with Single Bore + Fire = Hardened Long Straight Shaft with Single Bore

5. Stone Axe Head + Hardened Long Straight Shaft with Single Bore = Unfixed Stone Axe

6. Unfixed Stone Axe + Rope = Stone Axe

Offline

#14 2019-05-28 00:26:11

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

RECIPE 22: Tin Ore (Cassiterite) Mine

Tin is an essential component for the production of bronze, however it is a rare mineral on Earth (25X less abundant than copper, and 1800X less abundant than iron). In fact, tin deposits were so rare that tin trade was a characteristic and critical feature of Bronze Age trading economy. Nations that controlled tin were powerful by nature (having access to bronze), and few nations had that access. Phoneticians were notable for trading tin all over the mediterranean. Tin was so rare that archaeologists have little evidence for how tin was mined/produced/smelted.

At Earth's surface, tin is present only as Tin Oxide (Casserite), which is a black and heavy ore. Unlike copper ore (green) or iron (red), tin is not particularly easy to identify. Very few tin mines were present in antiquity (some researchers have speculated that the amount of tin present in Cornish/other mines simply couldn't have produced enough tin for the entire bronze economy). It is speculated that much tin "mining" was done instead by "placer mining" (similar to panning for gold) in river beds.

Since OHOL lacks rivers, for the time being, conventional tin mines will have to take their place.

Formula -

1. Casserite Vein + Bronze Pick (or any tech pick) = Casserite + Bronze Pick (-1) + Casserite Vein (-1)

2. Casserite Vein (last use) + Bronze Pick = Casserite Pit + Bronze Pick (-1)

3. Casserite Pit + Stanchion Kit = Casserite Mine

4. Casserite Mine + (Action) = Casserite + Casserite Mine (-1)

Offline

#15 2019-05-29 03:10:33

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

RECIPE 23: Shallow Pit

I was working through the bronze tech tree, and the issue that I realized is that currently in OHOL we skip directly to iron-age-level tech (bloomery furnaces). Iron age furnaces fire at higher temperatures than neolithic/bronze age furnaces were capable of obtaining, and the invention of bloomery furnaces were the critical bottleneck invention that enabled human civilizations to break into the iron age. Consequently, if any form of bronze tech is desired as a step before iron, it's absolutely necessary to work back to the neolithic/bronze age firing techniques.

I did some research on this, and it turns out that in OHOL we have the following historic inaccuracies: (A) open campfires, (B) ceramic ovens/kilns coming first.

In most early civilizations (and even in the medieval era), the preferred form of hearth was the pit-hearth -- in other words, a fire that is built in a pit in the ground. A firepit was preferred in many instances because it was easier to control if you built it inside of a flammable tent/teepee/hut, and furthermore it could double for many useful cooking purposes. It turns out that neolithic/bronze age cooking/baking/smelting was all done in some variant of an earthen pit. There were earth ovens, and pottery was first fired in pit kilns. Early smelting was likely also done in pits -- even if discovered by accident.

All of these methods start with a (shallow) pit, which is the foundational step of this recipe series.

Note that OHOL also has a "Trash Pit" (requiring shovel), but neolithic tech will not work if it depends on steel tech. I searched quite hard for something like a "stone shovel", but that simply didn't exist. Primitive people seem to have worked just fine with digging sticks.

Formula:

1. Pit Stakes + Skewer = Shallow Pit

2. Pit Stakes + Shovel = Shallow Pit

3. Shallow Pit + Bowl of Fertile Soil = Clay Bowl (Pit is destroyed)

4. (For trash pit) Shallow Pit + Shovel = Trash Pit + Shovel

RECIPE 24: Pit Hearth

1. Shallow Pit + Kindling = Pit Hearth

RECIPE 25: Fire Pit

To incentivize the use of Fire Pits (IRL, their advantage is ease of control), Fire Pits should burn longer than open fires.

1. Pit Hearth + Firebrand = Fire Pit + Firebrand

2. Fire Pit + Firewood = Large Fire Pit

3. Fire Pit + (Time) = Pit of Hot Coals

4. Pit of Hot Coals + (Time) = Pit of Ash

5. Pit of Ash + (Time) = Shallow Pit

Just for fun, Fire Pits are actually great from a cooking standpoint because Pit Barbecues are conceptually simple and beautiful. Years ago, I struggled with figuring out how someone might build the platform to support cooking over an open fire. Our imagination might lead us to build something like this (modern man "pretending" to be primitive):

But it turns out... building this elaborate set of supports and stakes is incredibly stupid (lychee is a dummy!) because all along you could have just done this:

And it turns out this pit style of cooking is the prevalent way to cook all through history. A whole host of ethnic foods involve some variant of pit cooking, which I won't go over in detail, but is in great abundance on Google.

Last edited by lychee (2019-05-29 21:30:15)

Offline

#16 2019-05-29 04:25:22

- Starknight_One

- Member

- Registered: 2018-10-15

- Posts: 347

Re: Recipe Suggestions Mega-Thread

For digging a pit, rather than tilling a row, one could use a crude mattock made from a tied long shaft and mouflon horns... it could also dig up soil pits, tule stumps, and clay pits. One could remove the horns from a mouflon skeleton with a sharp stone or hatchet.

Steam name: starkn1ght

The Berry Bush Song

The Compost Cycle

Gobble-uns!

Offline

#17 2019-05-29 05:01:43

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

RECIPE 26: Pit Kiln

Pit-firing pottery is the oldest method of firing pottery in the world -- and it is still used today in some parts of the world.

The advantages of pit-fired pottery is that it is easy to scale (just need a bigger hole), simple, and straightforward. The disadvantages are that earthenware are more likely to break during pit firing (less stable temperatures), more fuel consumption (not as efficient), and the inability to reach higher temperatures. Notably, pit-firing is unable to reach temperatures necessary to produce many glazes (shiny/smooth/colorful/texture) for pottery.

In OHOL, pit firing can balanced such that up to three pottery items can be fired at once, and consumes two kindling. Later pottery kilns will have increased fuel efficiency over this baseline. There is also a 15% chance that the firing process fails and only broken pottery shards are obtained.

Formula:

1. Shallow Pit + Kindling = Pit Hearth

2. Pit Hearth + Wet Clay Bowl/Plate (up to three) = Pit Hearth with Wet Clay Pottery

3. Pit Hearth with Wet Clay Pottery + Kindling = Filled Pit Kiln

4. Filled Pit Kiln + Firebrand = Firing Pit Kiln + Firebrand

5. Firing Pit Kiln + (Time) = Shallow Pit with Clay Pottery (Successful - 85%)

6. Firing Pit Kiln + (Time) = Shallow Pit with Broken Clay Pottery (Failure - 15%)

7. Shallow Pit with Clay Pottery + (Action) = Clay Bowl/Plate + Shallow Pit with Ashes

Last edited by lychee (2019-05-29 05:03:41)

Offline

#18 2019-05-29 14:13:39

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

RECIPE 27: POND (Redistribution)

This is a balance suggestion. Ponds should appear in other biomes (rather than only swamps), to support greater variety to early-game play and remove the meta sense that ("all villages need to be built next to green/swamps"). Swamps should contain the greatest frequency of swamps, but the occasional swamp should still appear in the green biome.

Also empty ponds should be dug up with a shovel to be destroyed.

RECIPE 28: WATERHOLE AND OASIS

These objects almost equivalent to a pond, except are aesthetically different. Waterholes appear in savannahs, and the oasis in the desert (very very rare).

For interesting-ness, waterholes could contain more uses than a pond, however they are intended to be very rare.

RECIPE 29: NATURAL SPRING (REVISION)

The grid spawning is rather unnatural. I think the game would be more interesting with random Natural Spring spawns, and Eve's already spawn on top of Natural Springs, guaranteeing a semi-viable start site.

Last edited by lychee (2019-05-29 14:17:33)

Offline

#19 2019-05-29 14:23:36

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

RECIPE 30: FOX

Trapping for fox fur was a major industry for northern latitude cultures. Here, I propose that foxes serve as the equivalent of rabbits in the arctic biome. Foxes could have evasive behavior.

To trap a fox, place a snare on the ground. If a fox walks over it, it is trapped.

Try to trap foxes with cubs. Trapping a fox with a cub will eventually cause the fox to respawn (similar to family holes).

Foxes yield twice as much fur compared to rabbits. (Skinning a fox produces two small furs).

Last edited by lychee (2019-05-29 14:25:02)

Offline

#20 2019-05-29 14:33:32

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

RECIPE 31: BANANA LEAF CLOTHES

This recipe series is intended to provide a quick solution to nudity (providing only minimal insulation). Banana-leaf clothes should be the worst clothes in the game, providing something like 5% insulation per item.

I've made clothes craftable with either needle+thread or rope (to encourage use of minimal clothing at any early technology phase of the game).

Formula:

1. Empty Banana Tree + (Action) = Empty Banana Tree + Banana Tree Leaf

2. Banana Tree Leaf (Stackable) + Needle and Thread = Clothing + Needle

3. Banana Tree Leaf (Stackable) + Rope = Clothing

The recipe series for banana tree leaves:

- 1 leaf = banana tree skirt

- 2 leaves = banana tree top

Offline

#21 2019-05-29 21:29:19

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

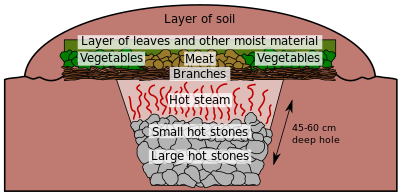

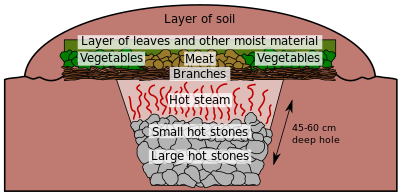

RECIPE 32: EARTH OVEN

Earth Ovens are the earliest ovens in the world -- built as a pit in the ground. Bake breads and roast any kind of meat in an earth oven, but don't try to bake a pie... that just sounds like a bad idea.

As a side note, all kinds of meats should be edible/bakable in OHOL when they're not -- pork, rabbits. It would be cool if adding seasoning does something special to the food too.

Formula:

1. Shallow Pit + Kindling = Pit Hearth

2. Pit Hearth + Firebrand = Fire Pit + Firebrand

3. Fire Pit + (Time) = Pit of Hot Coals

4. Pit of Hot Coals + Raw Food (up to three) = Pit of Coals and Food

5. Pit of Coals and Food + Property Fence Twigs = Uncovered Pit Oven with Food

6. Uncovered Pit Oven with Food + Bowl of Soil = Covered Pit Oven with Food + Bowl

7. Covered Pit Oven with Food + (time) = Pit Oven with Cooked Food

8. Pit Oven with Cooked Food + action = Cooked Food + Shallow Pit of Ashes

Offline

#22 2019-05-29 22:15:04

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

RECIPE 33: LEAD ORE (GALENA) SMELTING

Lead ore (galena) is actually quite abundant and easily smelted (low melting temperature at 327C), and consequently it was well-known in antiquity. However, it did not have much impact, as there were few uses for lead (except perhaps as ammunition for slings) since it was too soft to make tools with. Cast lead balls have been recovered in the archaeological record since 6500 BCE.

The original major use of lead in the Roman Empire was for making lead pipes for plumbing (lead in latin = plumbum). Lead is the easiest abundant metal to melt, shape, and cast. In fact, human civilizations has used lead pipes up until WWII -- which is when we first realized there is a health hazard associated with lead poisoning.

They show up here (early) in this recipe mega-thread because it's noteworthy enough to mention in the earliest smelting technology. First, Galena (lead sulfide) is oxidized by roasting. Then, because of its low melting temperature, galena can in fact be smelted in a typical fire pit. The efficiency of lead smelting can be improved by adding charcoal to the crucible (although this is entirely optional).

Formula (Roasting Galena -- can also be done in any oven except pit oven):

1. Galena Ore + Clay Bowl = Bowl with Galena Ore

2. Bowl with Galena Ore + Hot Coals = Bowl of Roasting Galena Ore

3. Bowl of Roasting Galena Ore + (Time) = Bowl of Roasted Galena Ore

4. Bowl of Roasted Galena Ore + (Action) = Roasted Galena Ore + Clay Bowl

Formula (Smelting Galena without charcoal):

5. Roasted Galena Ore (x2) + Clay Bowl = Bowl of Roasted Galena Ore (x2)

6. Tongs + Bowl of Roasted Galena Ore (x2) = Tongs with Bowl of Roasted Galena Ore (x2)

7. Tongs with Bowl of Roasted Galena Ore (x2) + Large Fire = Tongs with Bowl of Molten Lead (x1)

8. Tongs with Bowl of Molten Lead (x1) + (action) = Tongs + Bowl of Molten Lead (x1)

9. Bowl of Molten Lead (x1) + (time) = Bowl of Lead (x1)

Formula (Smelting Galena with charcoal):

10. Roasted Galena Ore (x1) + Charcoal (x1) + Clay Bowl = Bowl of Roasted Galena Ore and Charcoal

11. Tongs + Bowl of Roasted Galena Ore and Charcoal = Tongs with Bowl of Roasted Galena Ore and Charcoal

12. Tongs with Bowl of Bowl of Roasted Galena Ore and Charcoal + Large Fire = Tongs with Bowl of Molten Lead (x1)

13. Tongs with Bowl of Molten Lead (x1) + (action) = Tongs + Bowl of Molten Lead (x1)

14. Bowl of Molten Lead (x1) + (time) = Bowl of Lead (x1)

Formula (bad smelting recipe yields slag)

15. Roasted Galena Ore (x1) + Clay Bowl = Bowl of Roasted Galena Ore (x1)

16. Tongs + Bowl of Roasted Galena Ore (x1) = Tongs with Bowl of Roasted Galena Ore (x1)

17. Tongs with Bowl of Roasted Galena Ore (x1) + Large Fire = Tongs with Bowl of Slag

This recipe series generally reveals my philosophy towards smelting. Smelting tech is all about efficiency -- lower efficiency methods either burn more fuel or consume more raw ore to produce less final ore. Advancing up the smelting tree improves resource efficiency, and allows larger volumes to be performed at once.

I also think it would be an interesting game mechanic if performing the wrong recipes produce slag, raising the stakes for any kind of smithing/smelting.

Offline

#23 2019-05-30 19:47:49

- lychee

- Member

- Registered: 2019-05-08

- Posts: 328

Re: Recipe Suggestions Mega-Thread

RECIPE 34: TIN (CASSITERITE) SMELTING

Tin, out of the metals of antiquity, has the lowest melting temperature after mercury (liquid at room temperature) at 231'C. Consequently, it is the easiest ore to smelt (like lead, it does not need any special furnace, but unlike lead cassiterite does not require any preliminary roasting since it is an oxide). However, the rarity of tin meant that most civilizations encountered tin much later in their technological tree of advancement.

To review the abundances of classic metals: Iron (lots!) > Copper (50 ppm) > Lead (14 ppm) > Tin (2.2 ppm) > Silver (0.07 ppm) > Mercury (0.05 ppm) > Gold (0.001 ppm).

Formula (Smelting without Charcoal):

1. Cassiterite Ore (x2) + Clay Bowl = Bowl of Cassiterite Ore (x2)

2. Tongs + Bowl of Cassiterite Ore (x2) = Tongs with Bowl of Cassiterite Ore (x2)

3. Tongs with Bowl of Cassiterite Ore (x2) + Large Fire = Tongs with Bowl of Molten Tin

4. Tongs with Bowl of Molten Tin + (action) = Tongs + Bowl of Molten Tin

5. Bowl of Molten Tin + (time) = Bowl of Tin (x1)

Formula (Smelting with Charcoal):

1. Cassiterite Ore (x1) + Charcoal (x1) + Clay Bowl = Bowl of Cassiterite Ore and Charcoal

2. Tongs + Bowl of Cassiterite Ore and Charcoal = Tongs with Bowl of Cassiterite Ore and Charcoal

3. Tongs with Bowl of Cassiterite Ore and Charcoal + Large Fire = Tongs with Bowl of Molten Tin

4. Tongs with Bowl of Molten Tin + (action) = Tongs + Bowl of Molten Tin

5. Bowl of Molten Tin + (time) = Bowl of Tin (x1)

Formula (Bad recipe)

1. Produces slag if players attempt something else

RECIPE 35: PIT FURNACE

While lead and tin can be smelted in a conventional wood fire, the next series of ores require a higher temperature to smelt. To produce higher temperatures, adding oxygen (either through a blowpipe or bellows) and charcoal is absolutely necessary. There are a series of furnace designs sufficient to produce temperature at this tier, although the pit furnace (fire pit + bellows) is the most primive.

The following ores can be smelted at this furnace tier (e.g. pit furnace): Copper, Silver, and Gold. Iron requires a specialized furnace design, called a "bloomery", which will be covered later.

Note that furnaces that burn at higher temperatures produce more slag (melted waste product). Consequently, it is probably not a good idea to smelt lead/tin in higher tier furnaces, as the molten metal will mix with the slag.

Formula:

1. Shallow Pit + Bellows = Empty Pit Furnace

2. Empty Pit Furnace + Basket of Charcoal = Pit Furnace with Charcoal + Basket

3. Pit Furnace + Crucible (up to three) = Loaded Pit Furnace with Charcoal

4. Loaded Pit Furnace with Charcoal + Firebrand = Firing Pit Furnace

5. Firing Pit Furnace + (time) = Pit Furnace with Smelted Ore Crucible

6. Pit Furnace with Smelted Ore Crucible + (action) = Smelted Ore Crucible + Empty Pit Furnace

Note that this pit furnace design can only fire up to three crucibles with a single load of charcoal. Future furnace designs at this tier have better efficiency.

RECIPE 36: CHARCOAL PIT

This recipe is intended to replace the current method of producing charcoal on OHOL. Producing charcoal in pits was the most prevalent way of making charcoal in antiquity, and likely continues to the the predominent method to produce charcoal on a global/international scale today (source: UN Food and Agriculture Organization http://www.fao.org/3/X5328E/X5328E00.htm). Pit fired charcoal has lower yield than more advanced methods.

In this OHOL recipe, I've proposed what I anticipate to be a fairly controversial change -- that charcoal require firewood for production. There are two reasons why I've suggested this. (A) Realism. In real life, you can't make charcoal from just kindling; larger pieces of wood are absolutely required to form the charcoal. (B) Resource scarcity revision. Currently in OHOL, water and iron are the limiting features for a civilization, which is fine in principle, but actually fairly unrealistic when compared to actual history. In actual history, rather than water/iron, the primary limiting resource has virtually always been wood.

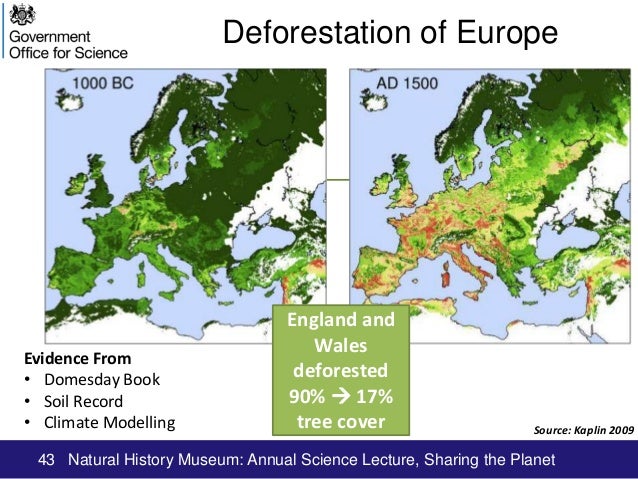

No matter where you look on Earth, mass deforestation (and it's consequences, such as desertification), is probably the largest impact that the human species has had on the planet. It's not iron or water scarcity. CO2 emissions is recent (on the geological scale), but steady deforestation has been the principle environmental impact of our species ever since the stone age. In fact, the rate of deforestation *improved* ever since the introduction of coal/natural gas, and consequently we don't talk about it much today since our modern economy no longer depends on wood, but circa 1500s, many European countries (particularly England) were hitting firewood shortages. Here's a really cool article: The Firewood Shortage That Helped Give Birth to America

Between about 1500 and 1660 Britain’s basic fuel supply, wood, began to fail, and after much re-adjustment over a prolonged crisis was replaced by coal.

The reasons for this growing shortage of wood fuel are various. Consumption of fuel increased as population grew and industry burnt more, while the supply seems to have dwindled as woodland of great antiquity was cleared to provide more cultivated land.

This growing shortage of wood manifested itself in a price inflation of astonishing magnitude. The cost of firewood was stable until the 1540s, yet it quadrupled by the 1580s and reached ten times its old level by the 1620s. Charcoal, though rather less seriously affected, followed the same pattern in a six-fold increase by the 1660s.

The whole period was, of course, one of general and rapid inflation, modest by modern standards but severe by comparison with anything before it; and firewood was affected more conspicuously than any other widely used commodity.

In short, by having charcoal consume firewood, there will be greater pressures on the wood economy. I would prefer to see wood scarcity over water or iron scarcity (it's more historically accurate), and I would propose to loosen the pressures on water (early wells could yield *much* more water before running dry) in exchange for an increased pressure on wood.

Formula:

1. Shallow Pit + Kindling = Pit Hearth

2. Pit Hearth + Firebrand = Small Pit Fire

3. Small Pit Fire + Firewood (or log) = Large Pit Fire

4. Large Pit Fire + Basket of Fertile Soil = Firing Charcoal Pit

5. Firing Charcoal Pit + (time) = Charcoal Pit

6. Charcoal Pit + Basket = Basket of Fertile Soil + Uncovered Charcoal Pit

7. Uncovered Charcoal Pit + Basket = Basket of Charcoal + Shallow Pit

Higher tier charcoal kilns will yield more charcoal per firing.

-------

Bookmark for iron bloomery: https://www.haraldthesmith.com/iron-sme … ce-design/

Offline

Pages: 1